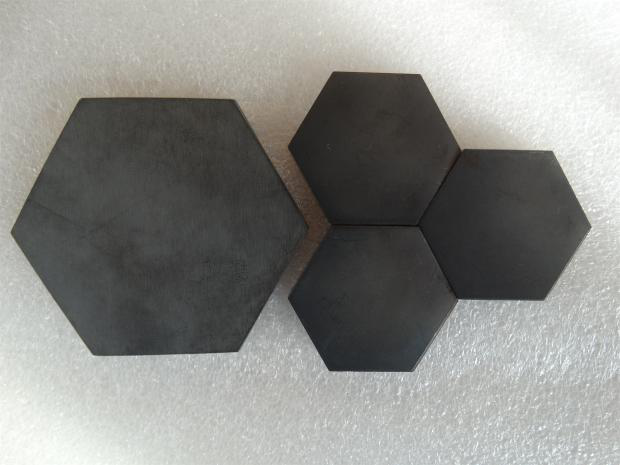

Seven Forming Processes of Silicon Carbide Ceramics

Silicon carbide ceramic material has excellent properties such as high temperature mechanical strength, high hardness, oxidation resistance, radiation resistance, corrosion resistance, thermal stability, small thermal expansion coefficient, and good chemical corrosion resistance. RBSIC Silicon carbide ceramic has been widely used in many fields such as industrial machinery, national defense semiconductors, environmental protection, nuclear energy, etc.

The preparation technology of RBSIC products ceramics mainly includes reaction sintering, atmospheric pressure sintering, hot pressing sintering, Hot isostatic pressing sintering, electric discharge sintering, oscillating reaction sintering carbon, etc. or heating the green body under inert atmosphere until the silicon melts into liquid and penetrates into the green body containing pores by capillary action. Liquid silicon or silicon vapor reacts with C in the green body, resulting in in-situ formation β- SiC combines with existing SiC particles in the body to form reaction sintered silicon carbide ceramic material.

The key to the performance of reaction bonded silicon carbide ceamic mainly lies in factors such as the size and type of carbon source, particle size of silicon carbide raw materials, porosity of the green body, sintering temperature, and holding time. The advantages of Reaction sintered silicon carbide ceramic are low sintering temperature, low production cost, and high degree of material densification, especially the almost no volume shrinkage during the reaction sintering process. Silicon carbide product is particularly suitable for the production of large-sized and complex shaped structural components. Silicon carbide product typical application products include high-temperature kiln furniture materials, radiation tubes, heat exchangers, desulfurization nozzles, etc.

Other six Forming Processes of Silicon Carbide Ceramics are Atmospheric pressure sintering, hot pressing sintering, Hot isostatic pressing sintering, spark plasma sintering flash sintering, shock pressure sintering.